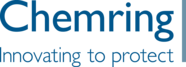

The Challenge

A multitude of industrial inspection tasks require highly skilled inspection engineers with years of experience to ensure that components are manufactured to demanding specifications. It’s often difficult to maintain and grow the number of non-destructive testing specialists, which means manufacturers struggle to maintain the accuracy and consistency of their product.

The Approach

We used our heritage in computer vision technologies to develop a measurement system, combining computer vision, artificial intelligence, machine learning, optical design and related techniques to reliably automate inspection tasks, enhancing the capability and reducing the burden on test specialists.

THE OUTCOME

We delivered an automated inspection system which greatly reduces the inspection time of a component, while improving the accuracy and repeatability of the tests. The system integrates with current inspection processes, allowing human experts to intervene if necessary. Our toolkit of measurement techniques is easily extended to address changes and new tests.

Related news, insights and innovations

Find out more about our cutting-edge expertise.